VR Training & Simulation for Industrial

& Manufacturing Companies

Why VR Training Matters for Industry

Training industrial teams in real environments is costly, risky, and difficult to standardize. At Grayscale by Ophir Studio, we build advanced VR training simulations, industrial virtual environments, and 3D technical training tools that enable companies to train their workforce in realistic, immersive, and risk-free virtual settings.

Our solutions improve safety, efficiency, and operational competency across facilities. We support VR onboarding, corporate training, machinery simulation, workplace safety, and industrial workforce development.

01

Enhanced Experiential Learning

02

Risk-Free, Controlled Environments

03

Standardized Procedures Across Teams & Sites

04

Faster Onboarding & Skill Development

05

Fewer Operational Errors

06

SNo Downtime Required

Our Solutions

We create custom VR simulations, digital twins, and virtual training programs designed for industrial and manufacturing environments.

These solutions support operator training, machinery simulations, onboarding, safety communication, internal presentations, and trade show experiences, helping teams understand complex machinery and workflows clearly and consistently.

01

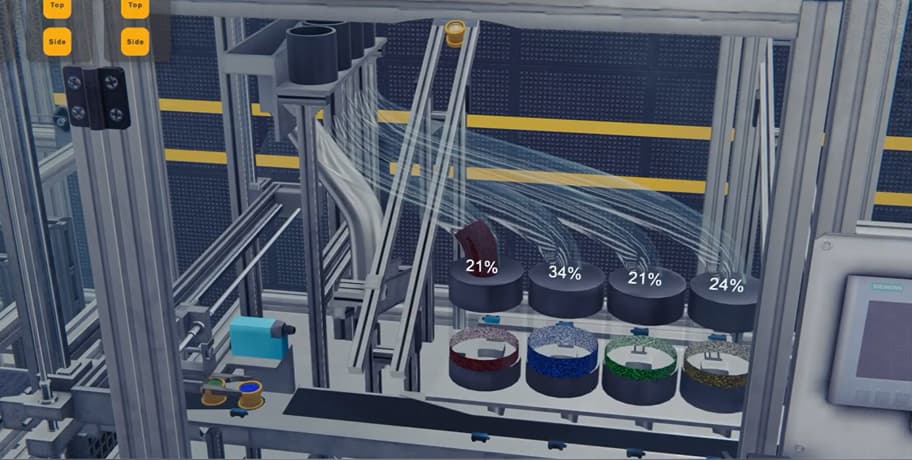

Machinery & Equipment Simulations

Realistic machine simulations for safe and accurate operator training, onboarding, production planning, and product demonstrations.

02

Production Line & Assembly Training

Step-by-step VR workflows that teach assembly processes, standardization, sequencing, and quality control with clarity and precision.

03

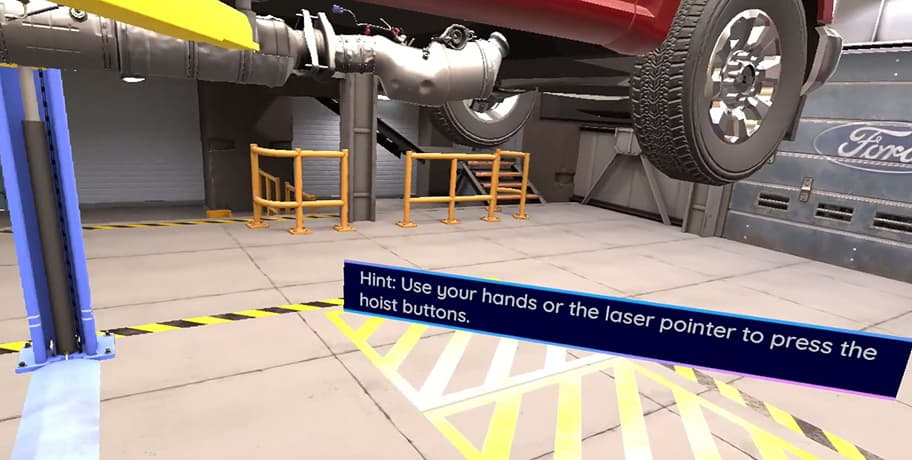

Maintenance & Troubleshooting Simulations

Detailed, repeatable VR modules that allow teams to practice maintenance tasks and troubleshooting without disrupting real operations.

04

Safety & Emergency Response (HSE)

Immersive safety scenarios that prepare workers for high-risk situations and strengthen safety culture across the organization.

05

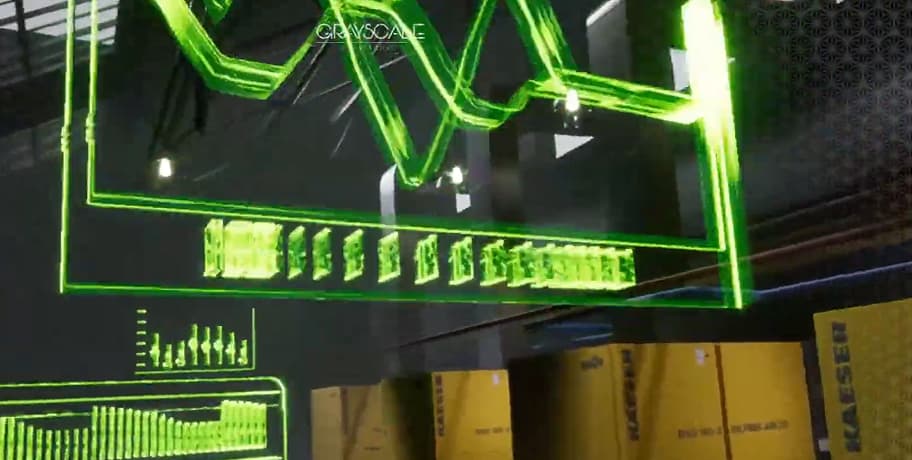

Digital Twins & Custom Environments

High-fidelity digital factories, virtual production lines, and custom industrial spaces for onboarding, process training, safety walkthroughs, layout testing, and stakeholder presentations.

Industry We Serve

Industrial Automation

Machinery & Equipment

Production Line Operations

Manufacturing Industry

Heavy Industry

Oil & Gas

Benefits & ROI

60-75% Faster onboarding

for new employees

30-50% lower training costs by reducing instructor time and equipment use

+40% Operator performance

improvement after VR-based practice

-43% Incidents

through VR safety training

+70% knowledge retention

compared to traditional training

-90% damage

to equipment during training phases

No downtime

for equipment or production lines

Why Grayscale by Ophir Studio

We are a specialist industrial VR training company focused on 3D technical simulations and interactive virtual training systems.

01

End-to-End Production, 100% In-House

02

Technical Precision Meets High-End Creative Execution

03

Expertise Rooted in Real Industrial Workflows

04