Digital twin vs simulation: differences, use cases, and real-world applications

Digital twin vs simulation: discover the differences, use cases, and real-world applications in the industrial sector. A practical guide for more informed decisions.

Digital twin vs simulation: differences, use cases, and real-world applications

In the context of modern industry, terms such as digital twin and simulation are often used interchangeably. In reality, they represent two distinct concepts, with different functions and applications across the lifecycle of a product, machine, plant, or industrial process.

For manufacturing, mechanical, engineering, and technology-driven companies, understanding the difference between digital twin and simulation is essential in order to make more informed investments, reduce risk, optimize processes, and enhance asset value through advanced 3D models.

In this article, we explore the digital twin vs simulation comparison, clarifying key differences, use cases, and real-world applications, with a focus on how advanced 3D supports business decision-making, product testing, and visualization throughout the entire industrial lifecycle.

What is a simulation

A 3D simulation is a digital model that reproduces the behavior of a system, product, or process under defined conditions. It is used to answer “what if?” questions by testing hypothetical scenarios without acting on the real world.

In the industrial sector, simulation models are commonly used to:

- verify machine functionality and component behavior

- analyze production flows

- test mechanical, thermal, or kinematic stresses

- validate design decisions before production

Simulations are static or time-bounded: they start from predefined parameters and return results related to a specific scenario. They are not connected in real time to the physical asset.

What is a digital twin

A digital twin is a dynamic, connected digital representation of a real asset. Unlike simulation, a digital twin is powered by real-time data coming from sensors, IoT systems, machinery, or enterprise software.

A digital twin:

- reflects the current state of the physical asset

- evolves over time together with the real object

- enables continuous monitoring, predictive analysis, and optimization

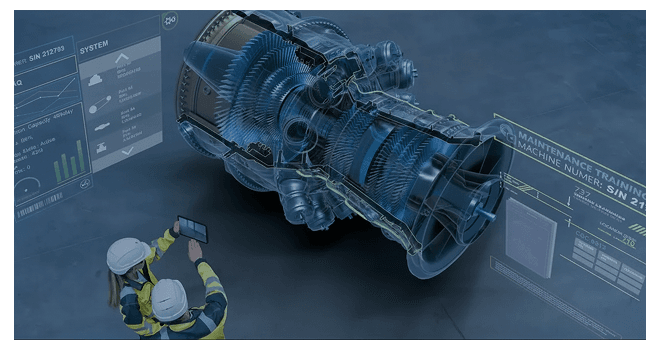

The digital twin is not only used to simulate future scenarios, but to understand what is happening now and what is likely to happen next, supporting operational decisions, predictive maintenance, and performance improvement. From a 3D perspective, digital twins integrate three-dimensional models, operational data, and advanced visualization, transforming complex information into clear decision-making tools.

Digital twin vs simulation: key differences

The difference between digital twin and simulation can be summarized through a few core aspects:

Data connectivity

Simulation uses static or hypothetical data, while a digital twin is connected to real-time operational data.

Time dimension

Simulation analyzes specific, limited-time scenarios. A digital twin accompanies the asset throughout its entire lifecycle.

Purpose

Simulation supports design and testing. Digital twins support monitoring, optimization, and operational decision-making.

Decision level

Simulation answers “what if?”, while digital twins answer “what is happening now?” and “what will happen next?”

In practice, simulation and digital twins are not competing technologies, but complementary ones.

Industrial use cases

3D simulation use cases

In industrial environments, 3D simulations are primarily used during the design, testing, and validation phases of products and processes. Key use cases include:

- product design and functional validation

- technical validation of components and complex systems

- testing of production processes and industrial workflows

- technical storytelling and industrial marketing to explain product functionality and benefits

Through simulation, companies can reduce development time, production costs, and design risks, while improving technical communication.

Digital twin use cases

Digital twins are mainly applied in operational management and continuous monitoring of industrial assets. Key use cases include:

- real-time monitoring of machines and plants

- predictive maintenance based on operational data

- optimization of production processes

- operational training based on real-world scenarios

- strategic decision support through advanced analytics

Within the Industry 4.0 framework, the digital twin becomes a central asset for improving efficiency, safety, and industrial competitiveness by integrating data, 3D models, and decision-making processes.

The role of advanced 3D models

Both simulation and digital twins rely heavily on advanced 3D models. These are not merely aesthetic visualizations, but functional tools that improve technical understanding, reduce errors and ambiguity, facilitate communication between technical teams, management, and clients, and support data-driven decisions based on clear scenarios. 3D therefore becomes a shared language across design, production, marketing, and training.

Conclusion: why choose Ophir Studio for digital twins and 3D simulation

Understanding the difference between digital twin and simulation is only the first step. The real value emerges when these solutions are designed and integrated correctly within industrial workflows.

At Ophir Studio, we develop 3D simulations and digital twins as strategic systems, not simple visualizations. Our approach combines technical expertise, advanced visualization, and real-world workflow integration, enabling companies to:

- make better-informed decisions

- reduce operational risks and costs

- improve communication, training, and performance

Whether it’s real-time data-connected digital twins or advanced simulation models, Ophir Studio acts as a technology partner, guiding companies in adopting advanced 3D solutions that deliver concrete, measurable, and scalable value.

Contact us for a free consultation.

FAQ

What is the difference between BIM and a digital twin?

BIM is an informational digital model used for design and construction. A digital twin is a dynamic representation connected to real-time data, enabling continuous monitoring and optimization of assets.

What is a digital twin?

A digital twin is a real-time virtual replica of a physical asset, continuously updated with live data and used for analysis, simulation, and decision support.

What is simulation?

Simulation is a digital model that reproduces system behavior in specific scenarios for testing, validation, and analysis, without real-time data.

Contact us!